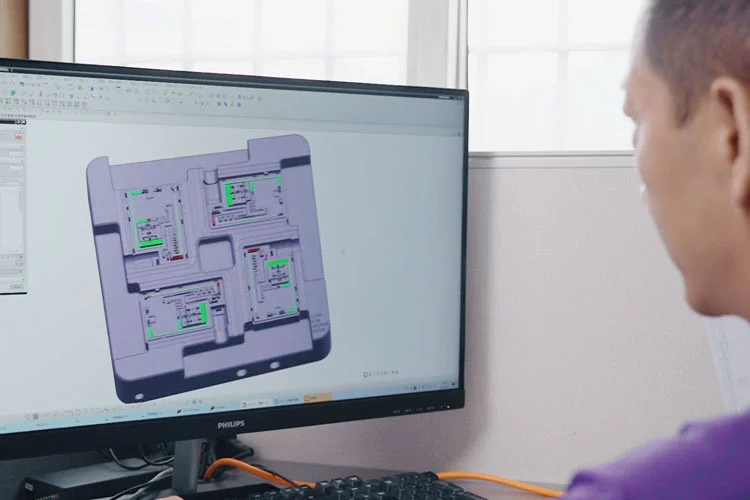

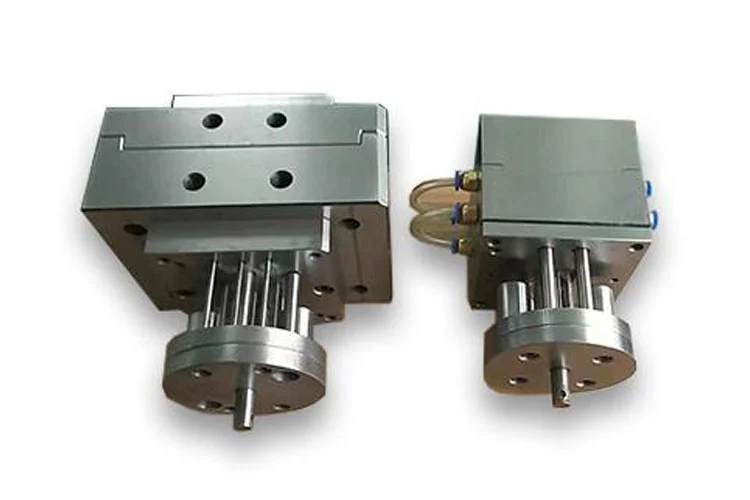

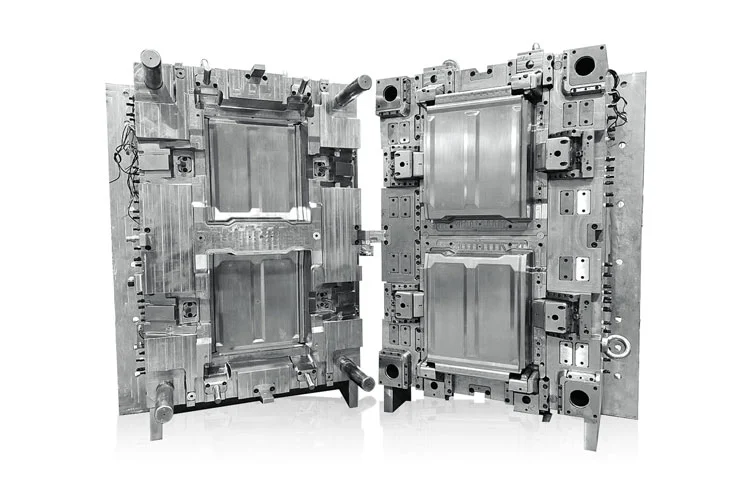

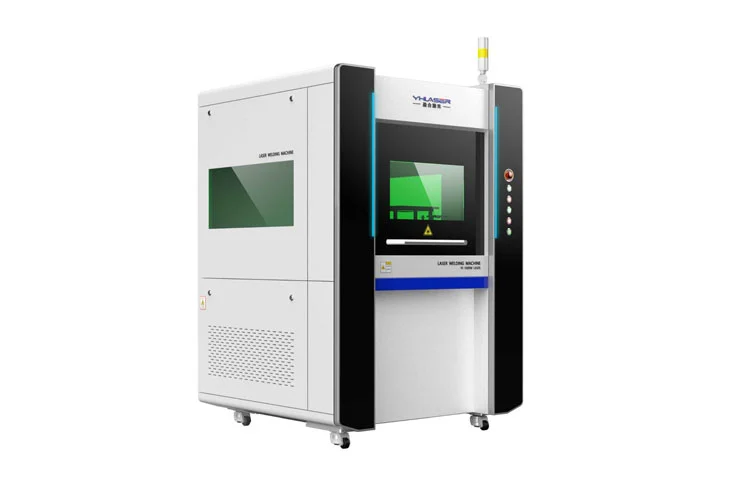

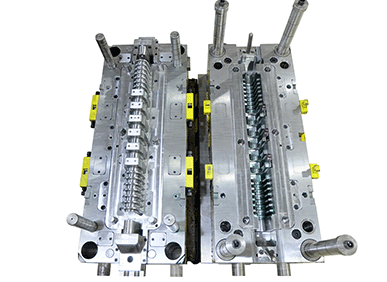

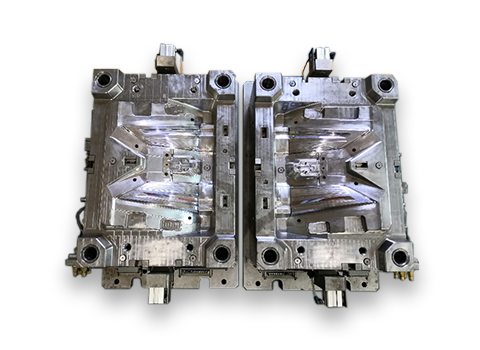

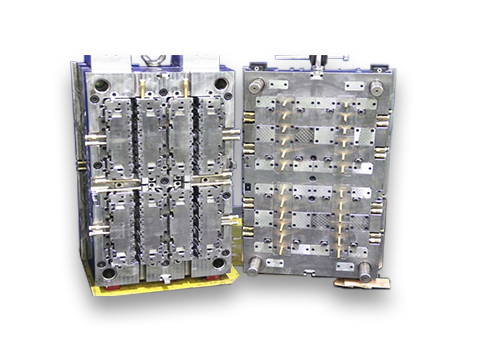

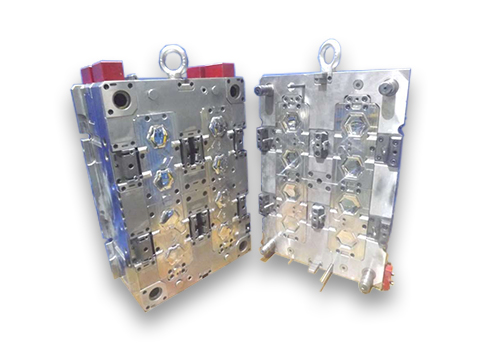

For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to our one-stop facility. We are keen to meet your injection molding needs with single and convenient sources. Thanks to our advanced equipment for tooling making and injection molding, Packson is able to handle all kinds of your needs of injection molding, mold making. Despite injection molding and mold making, we also specialized in making metal machining parts by CNC machines. We are proud to offer primary, comprehensive project management, leading-edge assembly line, product distribution, and logistics services that help you keep your company to be controlled well. Our mission has always been to assist customers to create high-quality parts with competitive prices and fast lead time. Learn more about how you and your business can take advantage of our services today.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español