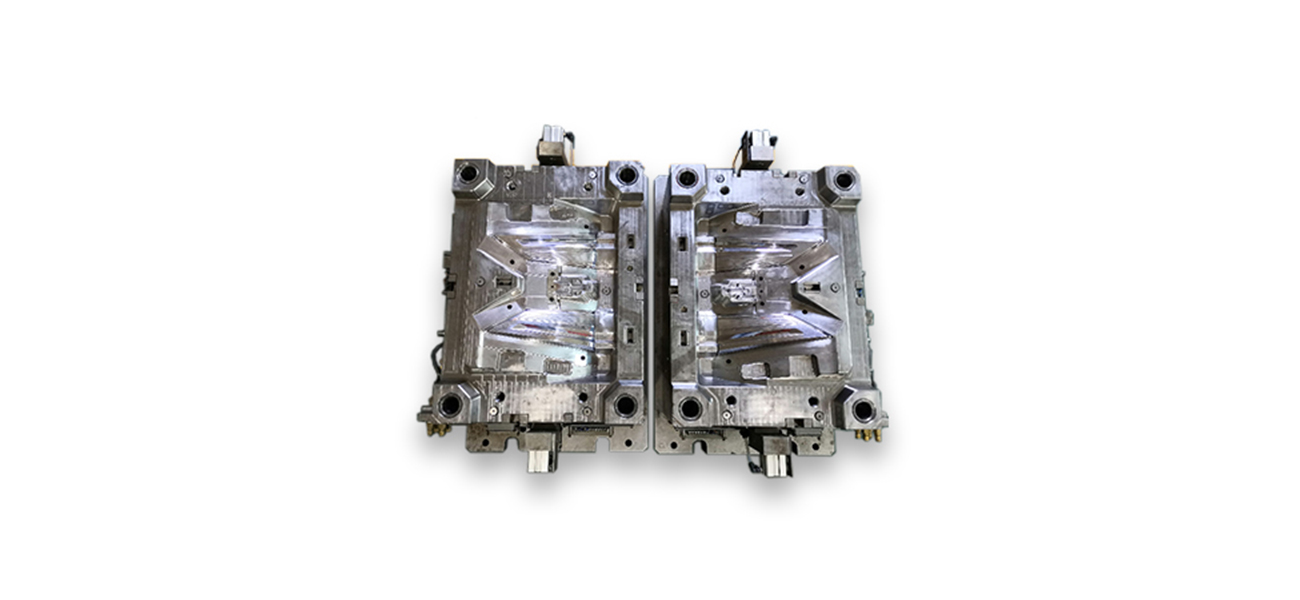

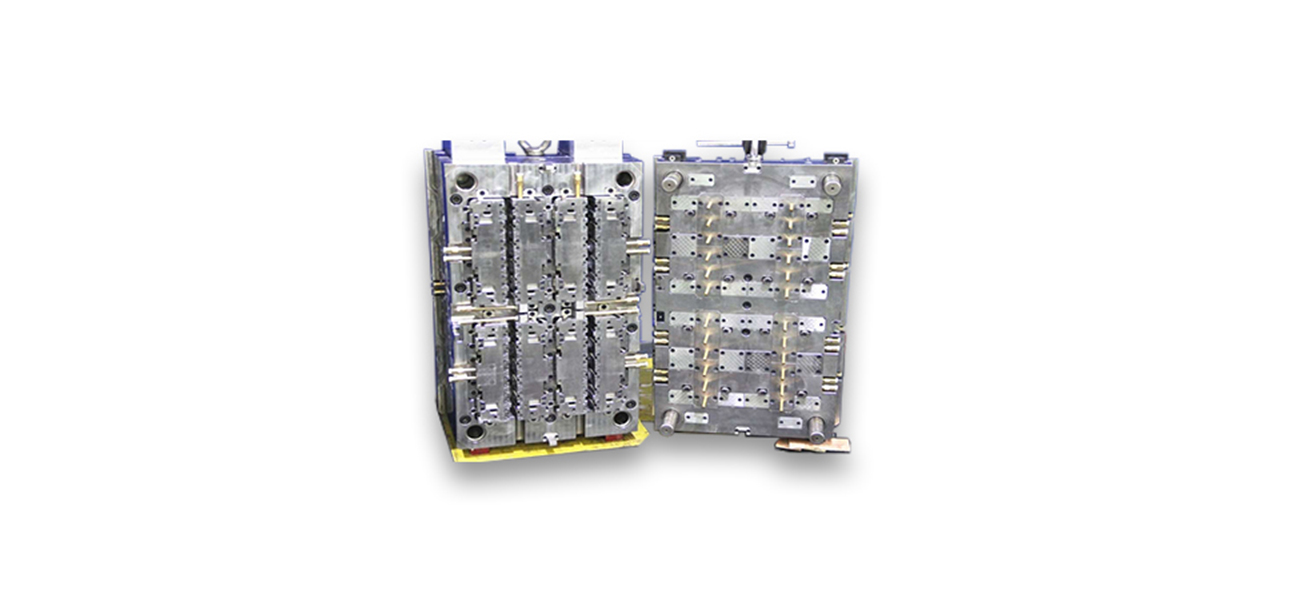

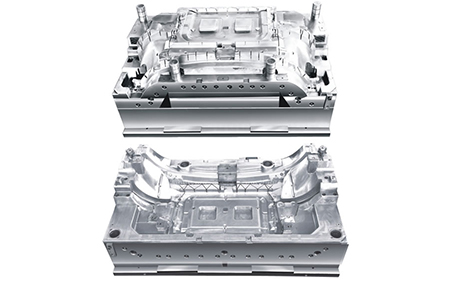

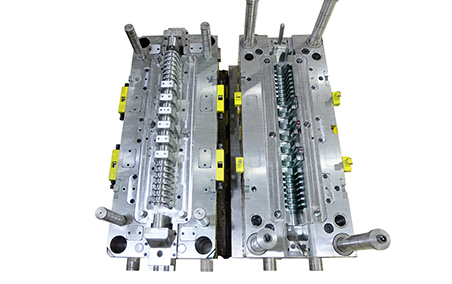

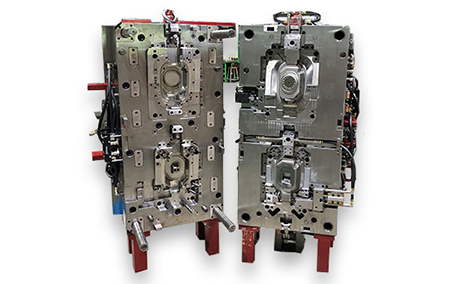

With over 15 years of experience in injection mold making,Packson starts mold business in 2006. We are your professional mold manufacturers who are able to provide high-quality, one-stop service and OEM injection mold making service. We offer qualified molds and injection mold making services to over 25 countries and regions like China, North America, Newzealand, Israel, Europe, etc. Our injection molded products are applied to a variety of industries like automotive, medical, electrical appliance, construction and so on.Packson mold manufacturers had passed the certification of ISO9001:2016 and ISO 13485:2016 which is the international standard of medical industry quality system. With the rapid development of the company, Packson's mold sales grow by 30% on average annually and we expand the injection mould production line for volume production for molding parts.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español