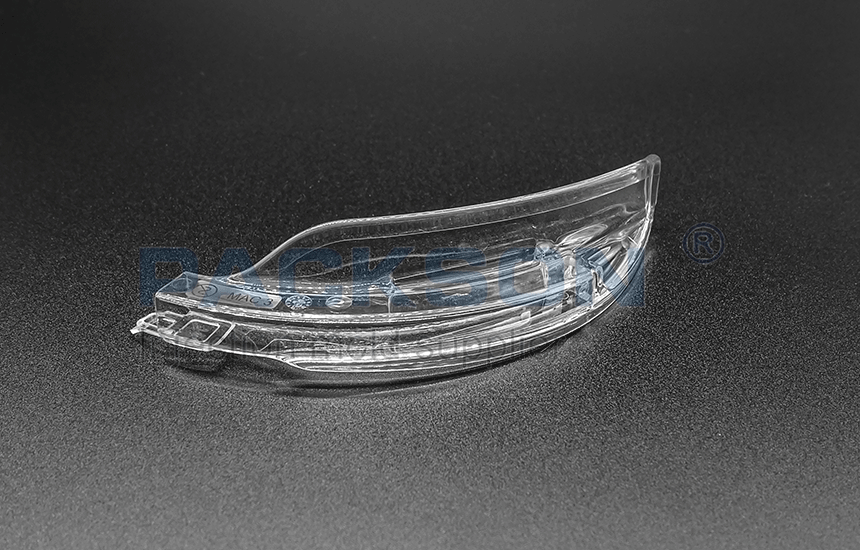

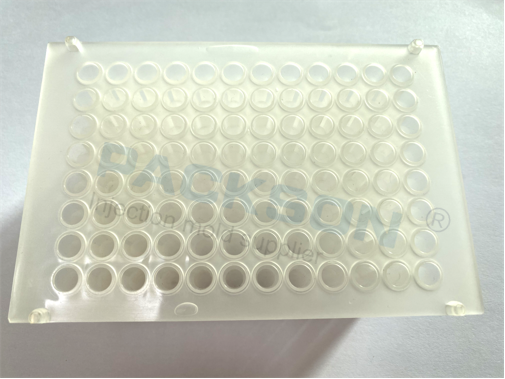

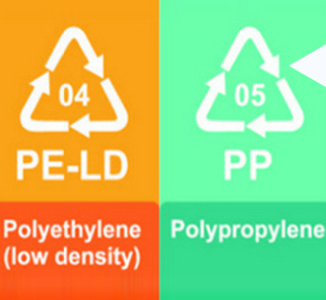

To be a qualified medical plastic components manufacturer, the most advanced technology and continuous compliance and certification are the pillars of success. Medical progress is advancing by leaps and bounds. We can't imagine how things are now being developed so quickly. It helps improve everyone's quality of life. Our cleanroom facilities are for medical plastic parts and liquid silicone rubber molding. They are all ISO certified to 13485 and 9001. We've been providing the best medical plastic parts production molding solution to BD for over 5 years. Please don't hesitate to contact us for competitive medical plastic solutions like Medical disposables, Medical devices, Medical plastic parts, Medical packaging, and Medical instruments.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español