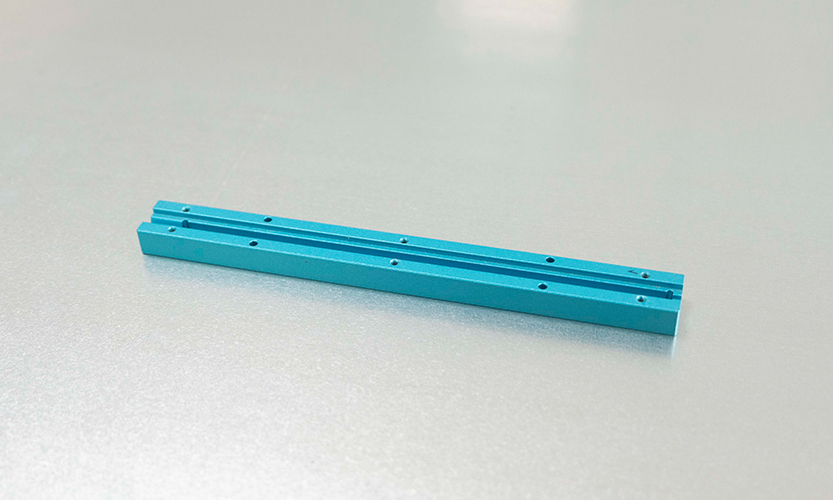

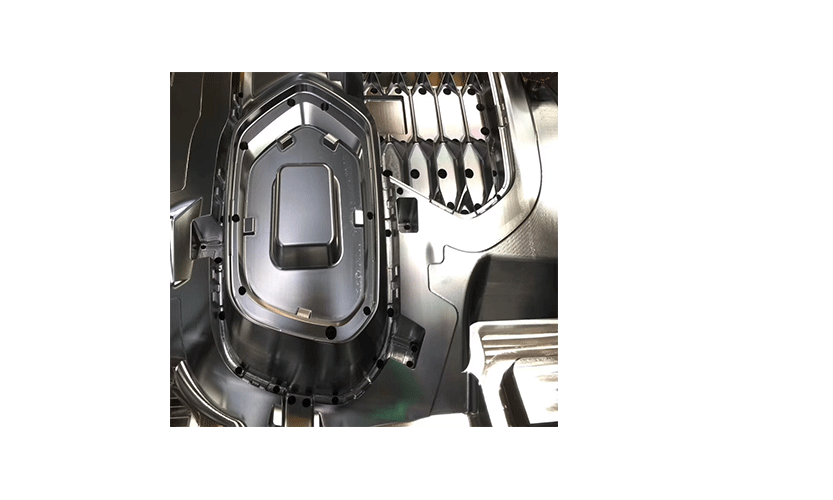

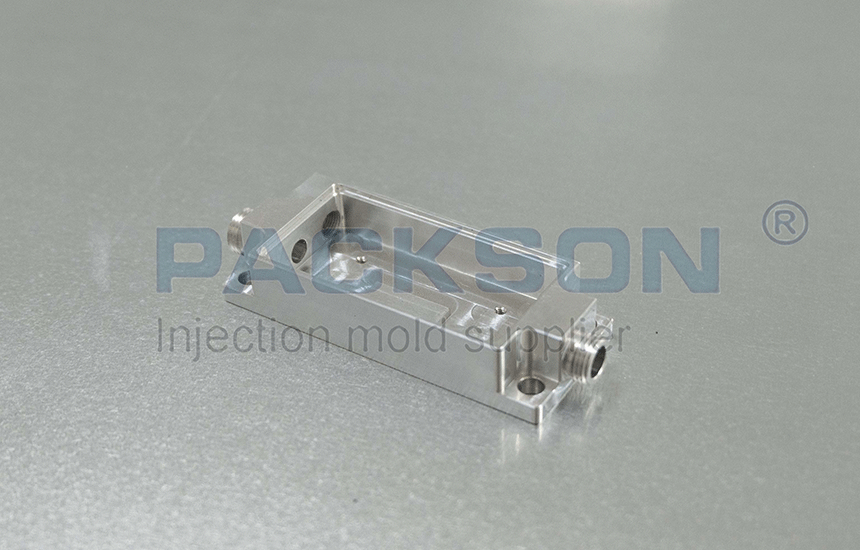

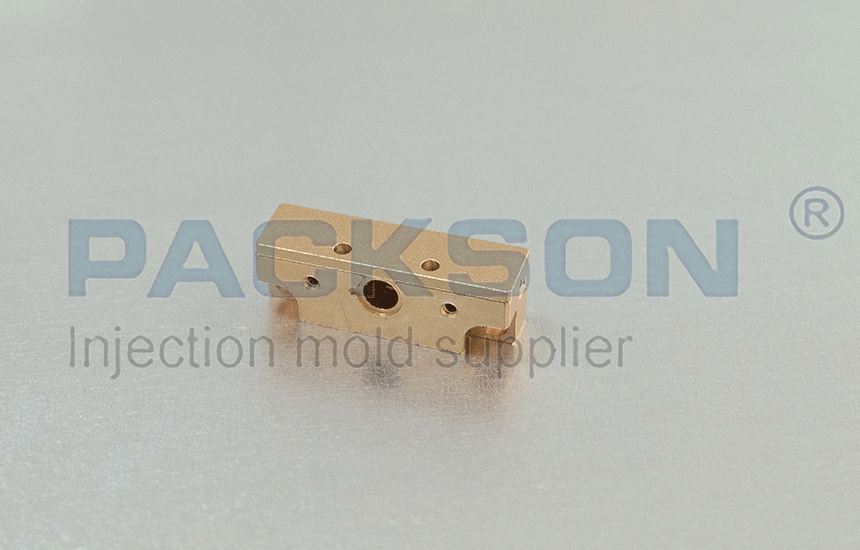

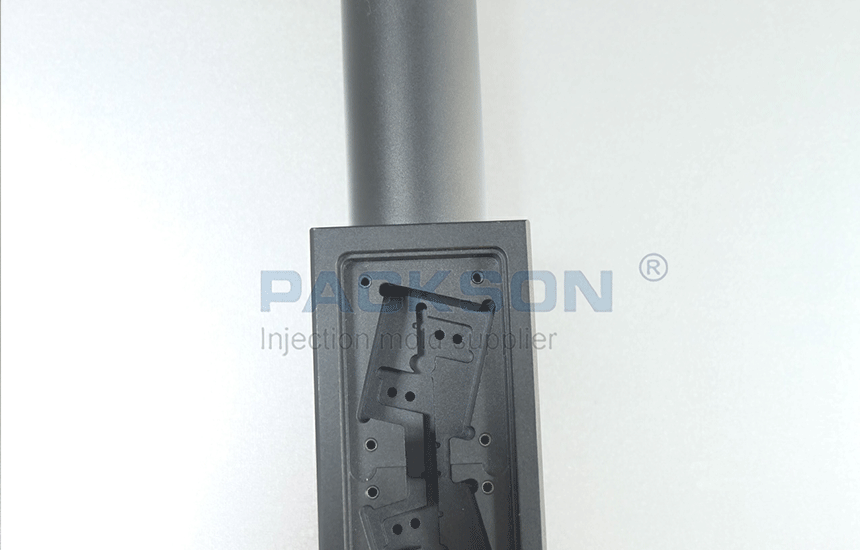

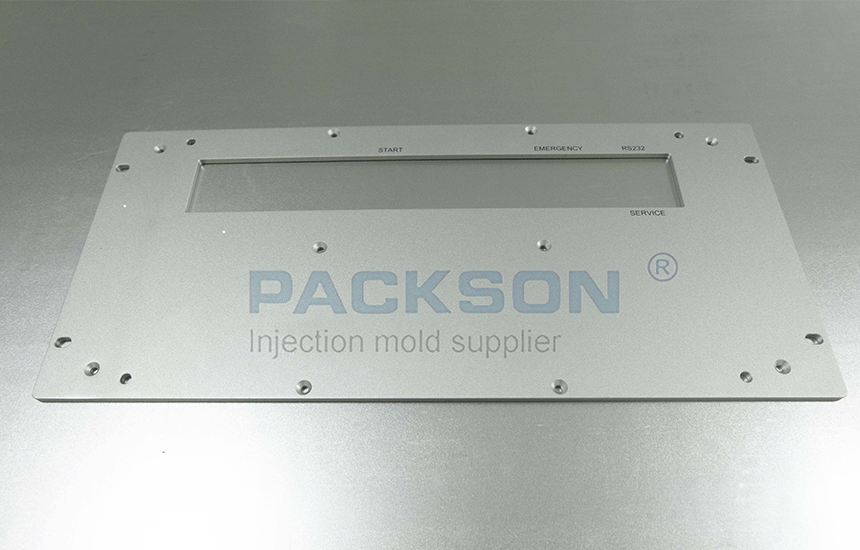

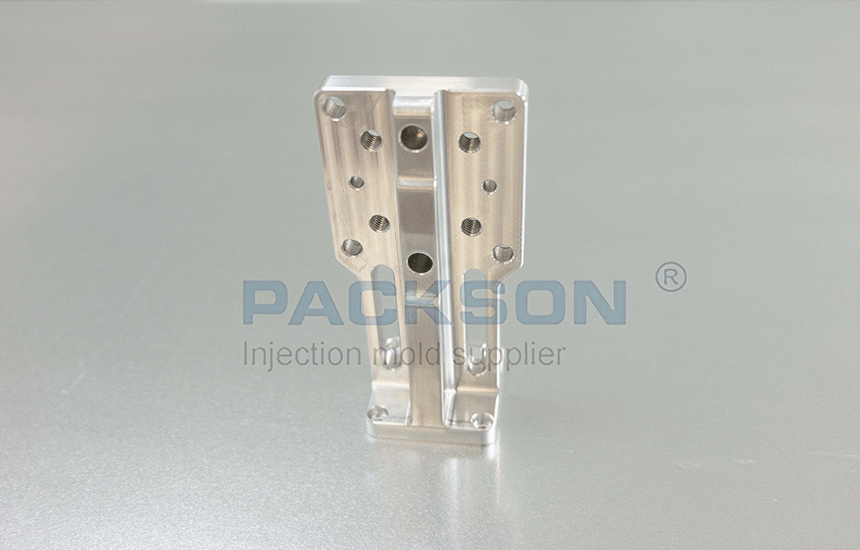

Packson provides our customers a various CNC machining services to our customers, including milling, turning, grinding, drilling and more.

Our teams are able to manufacture metal machining parts via our precision manufacturing machine such as 3,4, and 5 axis CNC machining centers on 2D and 3D CAD drawing from the clients. Regardless of whether you are in search of precision plastic, CNC aluminum, stainless steel parts, our production lines are able to a wide range of precision plastic or metal machining parts.

Packson also provides a free quotation and discuss the most efficient and suitable machining process for your project. Don't hesitate to contact our team.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español