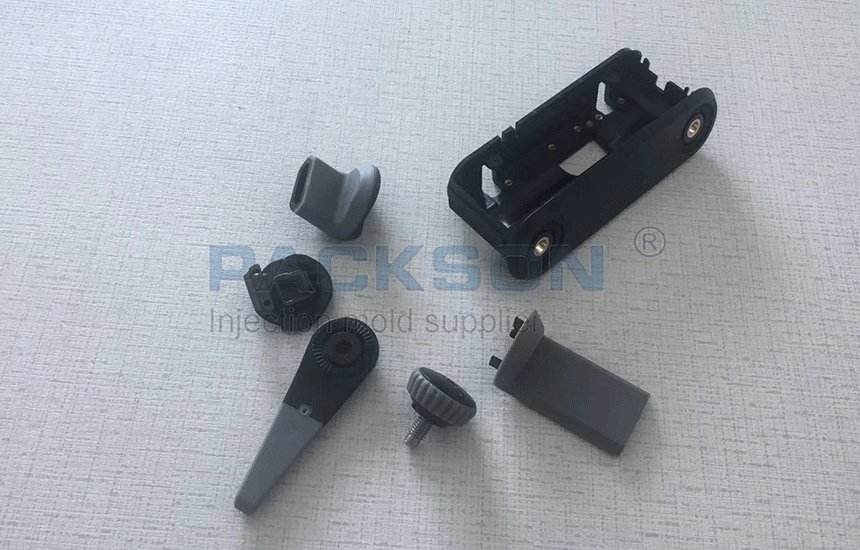

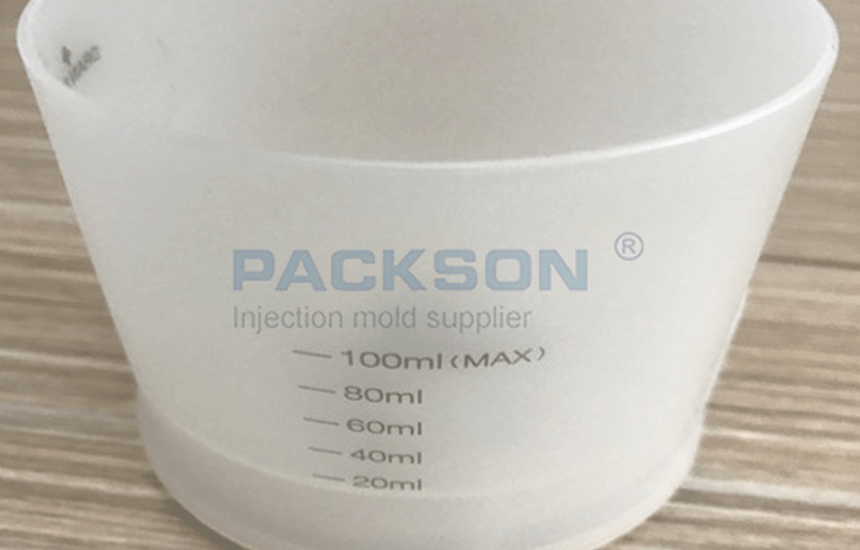

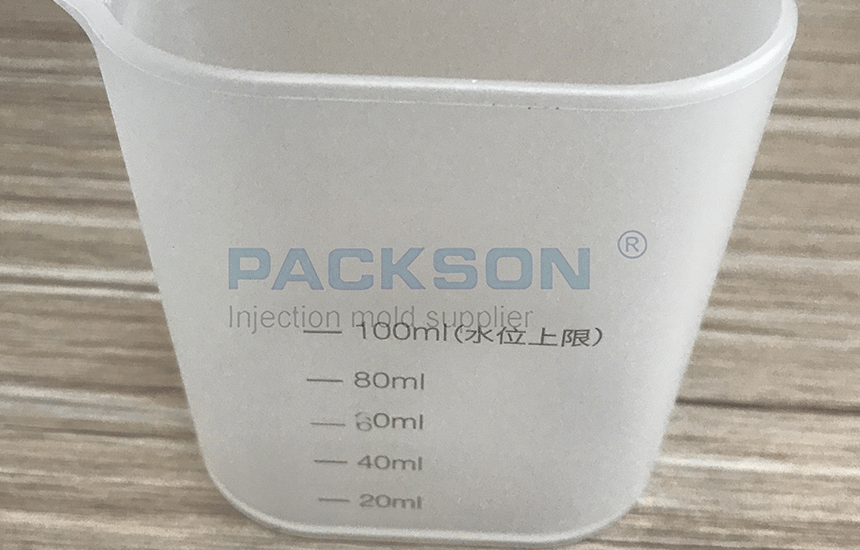

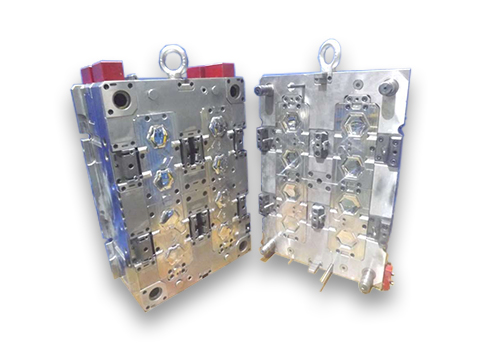

At first, Packson not only makes electrical plastic molding parts for customers but also helps clients to develop new electrical plastic molding parts like Bluetooth speakers. We focus on plastic injection molding for making electrical and electronic parts. Scientific molding is widely used at Packson to enable us to make products as efficiently and effectively as possible. Since 2006, we have been engaged in the injection molding business. We have professional knowledge and reputation to meet your products. You can rest assured to cooperate with us for any quantity of products. We will be 100% assure to pack high-quality products and send them to you from our over 10,000 square foot facility. Just contact or call us directly if you need an urgent solution for your project!

Other Popular Searches from Packson Mold:

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español