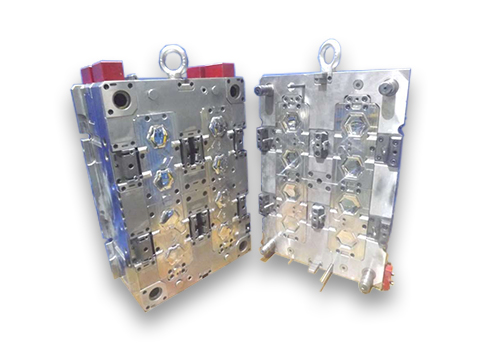

Packson's plastic multi cavity moulds have become an essential tool in the world of precision manufacturing. Designed to produce multiple identical components in a single injection cycle, these moulds have transformed the efficiency and scalability of plastic part production. Their widespread applications across industries reflect their adaptability, cost-effectiveness, and engineering precision.

Medical Industry: Enhancing Hygiene and Accuracy

In the medical field, where hygiene and dimensional precision are crucial, plastic multi cavity moulds offer unmatched performance. These moulds are used to produce syringes, blood sample tubes, IV connectors, and other medical disposables. The ability to produce consistent, sterile components in large quantities helps meet the strict regulatory standards of the healthcare industry.

Since every cavity in plastic multi cavity moulds is designed to produce an identical part, manufacturers can ensure high repeatability and extremely low defect rates. This precision helps minimize contamination risks and allows for efficient, high-speed production of life-saving equipment.

Consumer Goods: Meeting High-Volume Demands

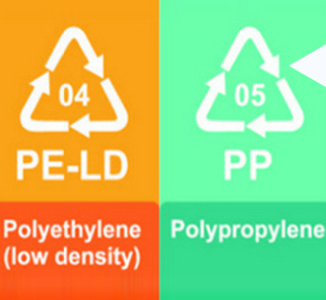

In the fast-paced world of consumer products, manufacturers need to produce plastic parts quickly and cost-effectively. Plastic multi cavity moulds play a vital role in making everyday items such as bottle caps, containers, kitchen tools, and personal care product components. With the capability to produce multiple parts in a single shot, these moulds significantly increase output while reducing cycle times.

By using plastic multi cavity moulds, companies can respond quickly to market demand and seasonal changes. This level of flexibility and speed is crucial for staying competitive in the consumer goods market, where time-to-market often determines a product's success.

Automotive Components: Consistency in Performance

The automotive industry demands reliable, durable, and consistently manufactured parts. Plastic multi cavity moulds are used to produce clips, brackets, interior trim elements, cable management parts, and connectors. These parts must withstand extreme temperatures, mechanical stress, and long-term wear.

Thanks to the precision engineering of plastic multi cavity moulds, manufacturers can ensure that each part produced meets tight tolerances and safety requirements. This not only enhances product quality but also reduces the need for manual inspection and rework. For global automotive suppliers, this consistency is essential to maintain quality control across production lines.

Electronics and Telecommunications: Micro-Precision at Scale

In electronics and telecommunications, miniaturization and precision go hand in hand. Plastic multi cavity moulds are employed to manufacture small, intricate components such as plugs, sockets, cable clips, and internal device structures. These parts must be both lightweight and durable, with excellent dimensional stability.

Plastic multi cavity moulds enable the mass production of such components without compromising detail or accuracy. Each cavity is carefully calibrated to produce exact duplicates, making the moulds ideal for high-tech applications where even the smallest deviation can cause a product failure. As demand for compact and reliable electronic devices increases, the importance of these moulds continues to grow.

Conclusion

Plastic multi cavity moulds are a vital asset in various manufacturing sectors, including medical, consumer, automotive, and electronics. They offer speed, precision, and efficiency—qualities that are essential in modern production environments. Whether it's about producing millions of identical parts or meeting the stringent quality requirements of regulated industries, plastic multi cavity moulds provide the flexibility and reliability manufacturers need.

With its deep expertise in mould design and production, Packson delivers plastic multi cavity moulds that meet the evolving demands of global manufacturing. Their solutions help clients reduce costs, improve product consistency, and scale production with confidence.

English

English  日本語

日本語  Deutsch

Deutsch  Español

Español