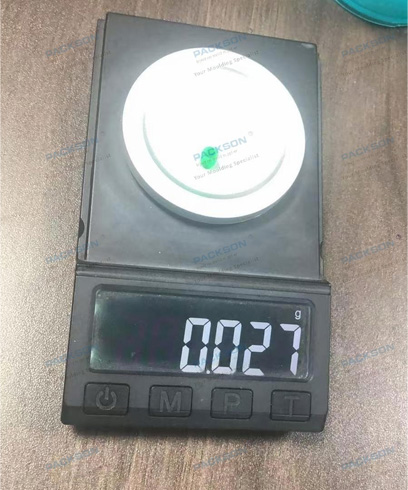

Packson's thrilled to share that our latest LSR (Liquid Silicone Rubber) product is incredibly lightweight, weighing in at just 0.027g! Can you believe it?

Thanks to our innovative approach, we can now utilize a cold runner with an open nozzle to inject parts directly. This breakthrough opens up new possibilities for efficiency and precision in manufacturing. This specific technique significantly refines the entire LSR molding process, dramatically reducing material waste, eliminating secondary de-gating labor, and ensuring extremely fast cycle times for all of our high-precision liquid silicone rubber components.

After relentless efforts from our dedicated team, we successfully tested our 1x4 cavity prototype molds, laying a solid foundation for future developments, including 1x32, 1x64, and 1x128 molds.

A big shoutout to the entire Packson team for their hard work and commitment! Together, we are pushing the boundaries of what's possible in LSR technology.

Let's keep innovating!