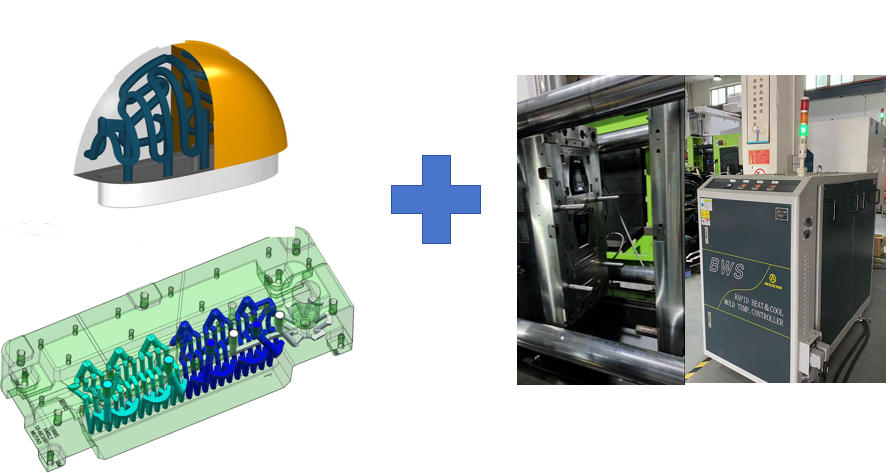

Packson stands out in the field of high-gloss injection molding. We utilize advanced additive manufacturing techniques to fabricate injection mold inserts and then perform meticulous polishing. This ensures a mirror-like surface finish on the molded parts while significantly reducing the risk of adhesion to the core.

Our mold inserts also feature cooling channels that are tailored to the product shape, with a spacing of only 4-5mm and evenly distributed. This facilitates rapid heat transfer and precise temperature control, further enhancing the surface quality.

Through these innovative technologies, Packson can not only achieve weld line-free and high-gloss products, but also guarantee a mold life of 500,000 to 1,000,000 injection cycles. This greatly improves production efficiency and cost-effectiveness.

You can fully rely on our expertise to achieve perfect injection molding results.

Packson has mastered the Rapid Heat Cycle Molding (RHCM) technology, which enables us to quickly adjust the mold temperature during the injection process. This not only eliminates surface weld lines but also significantly improves product gloss and mold transferability.

RHCM is a high-end injection molding technique, but Packson has fully mastered and proficiently applied it. When the mold is installed in the injection machine, we inject hot water to rapidly raise the mold temperature to the set value, and then immediately proceed with plastic injection.

Leveraging our extensive experience and technological advantages in high-gloss injection molding, Packson is undoubtedly the preferred partner for high-gloss or transparent plastic parts. We can ensure exceptional product surface quality while providing reliable production efficiency and consistent performance.

By choosing Packson, you will gain access to industry-leading high-gloss injection molding solutions, infusing your products with a captivating glossy allure.

#InjectionMolding #HighGloss #RapidHeatCycleMolding #SurfaceQuality #TransparentPlastic #MoldLife