In today's manufacturing industry, multi-cavity molds are highly favored for their ability to significantly increase production efficiency and reduce per-unit costs. However, designing and manufacturing precise multi-cavity molds is a complex task that requires advanced expertise and innovative solutions. This is where Packson stands out as the first choice for multi-cavity plastic injection molds.

The key to successful multi cavity molds design lie in effective temperature management. Conventional cooling methods often struggle to keep up with the demands of complex geometries and heavily ribbed contours, which place enormous stress on the temperature control system.

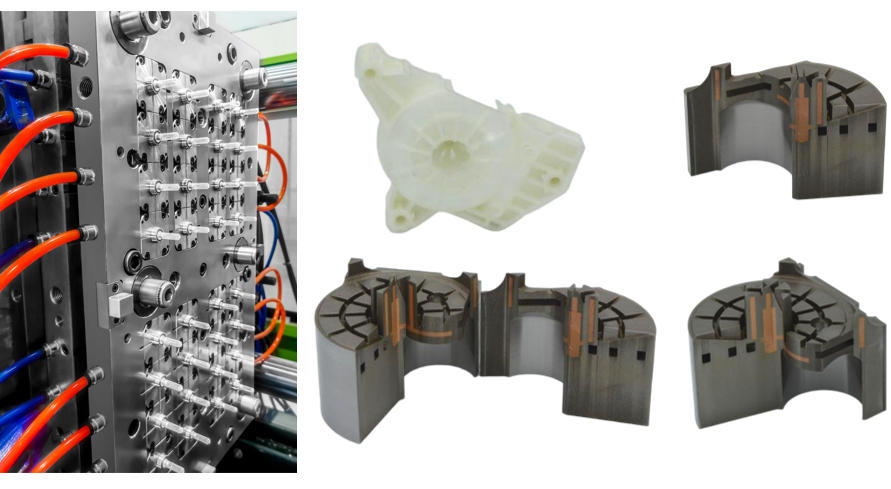

Packson's answer to this challenge is its innovative technology. By strategically combining copper and integrated cooling channels, we bring the cooling process directly to the hotspots within the mold. This targeted approach ensures that each cavity maintains a consistent temperature, enabling uniform cooling and reducing defects caused by temperature differences.

Precise temperature control is crucial in multi-cavity mold design. Packson's advanced heating and cooling systems, including electric heaters and water circulation systems, allow us to maintain the appropriate mold temperature throughout the production process.

Our symmetrical cooling channel layout further enhances the uniformity of temperature distribution, ensuring that each cavity receives the same level of cooling. This attention to detail translates into consistent product quality, minimizing the risk of defects and maximizing production efficiency.

Packson's expertise extends beyond temperature control. We also excel in the design of gate and runner systems for multi-cavity molds. Our selection of tab gates (edge gates) allows for more flexible positioning and effectively absorbs flow stress, mitigating the impact on the mold.

Moreover, our team of experts carefully designs the runner system to ensure even distribution of molten plastic into each cavity. By optimizing the length and diameter of the runners based on the material's flow characteristics, we prevent uneven flow and maintain consistent product quality.

With our extensive experience and technological prowess, Packson has established a proven track record in the production of high-quality multi-cavity molds. From the initial requirement analysis and design phase to the final production and testing, we apply our expertise at every step to deliver exceptional results.

By choosing Packson as your partner, you can trust that your multi-cavity mold projects will benefit from our innovative cooling solutions, precise temperature control, and optimized gate and runner design. This translates into increased production efficiency, reduced per-unit costs, and consistently excellent product quality.